ABOUT US

For over 20 years, we have been specialized in the production of sandwich panels.

Established in 2002 and located in province of Parma, T-Pan srl is a company specialized in the manufacture of sandwich panels.

The maximum realizable panel size is 14x3 metres in one piece without inserts.

The sandwich panels are mainly composed of GRP or aluminium facings and different foam cores.

We are provided with a CNC machining centre, 5 axis, dimensions 10x3 metres for the composite panels' processing: milling of the edges of the panels, door or window opening, drilling, thread, particular shape, etc.

Thanks to our production system we are able to process special working on the panels; this allows to use the panels in many applications: panels for refrigerated or insulated trucks, panels for caravans, cold rooms, rear doors for semitrailers, structural panels for architecture and building, advertising boards and all the applications requiring precision, lightness and mechanical resistance.

The steady demand for innovative solutions drove our company to pay special attention to the research and the selection of new materials and to the setting up of new structural solutions.

The outcome, for example, as regards the demand of weight reduction has been a special lightweight sandwich construction with an excellent strength-to-weight ratio, which has been developed together with our customers and partners who have given a big contribution to let T-Pan becoming one of the leading suppliers in Europe and leader in Italy in the manufacture, in “discontinuous system” of composite panels.

In order to supply sandwich panels with a very good aesthetic look we have given particular attention to structural composition and that's why we select the best raw materials.

A good dialogue with our customers has allowed us to optimize the production process as well, making it flexible and particularly reactive, assuring for the most part, fast deliveries.

HIGH QUALITY

At T-Pan we are committed to manufacturing high quality sandwich panels worldwide and right the quality of our products represents the greater force and the factor on which is based our production process.

RESPECT OF THE ENVIRONMENT

We pay a particular attention to the environmental matters as well as to the health of our workers. For this reason we have realized a production process without polluting substances, using raw materails and a working system which decreases at the minimum the risk for people and the environment.

PUNCTUALITY IN THE DELIVERIES

The punctuality in the deliveries regarding the taken engagements represents a further strength of our company making it an absolutely reliable partner, not causing any inefficiency for the customers.

GROWTH WITH THE CUSTOMER

We display openness towards the research and the collaboration with the customers in order to promote and implement creative and innovative ideas and solutions.

T-PAN TECHNOLOGY

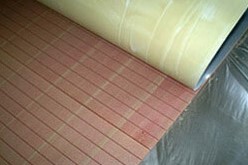

Thanks to our most advanced technologies, the technical qualities of our panels and their design are of extremely high standards. The aim is to obtain the greatest mechanical and dimensionalperformances of the finished product. This is possible thanks to a vacuum pressing system, in discontinuous, which allows to obtain really painstaking and high quality sandwich panels. The maximum dimensions of the panels are 14x3 metres in one piece, without inserts. The above-mentioned characteristics are guaranteed by a production technology based on the previous automated mixing and the next “hand-made” gluing with the two components polyurethanic glue which enables our workers to verify the uniform spread of the glue and to know for certain to obtain a very compact product without air in the sticking areas.

After having been pressed the panels are squared and milled on a CNC machining centre, 5 axis, dimensions 10x3 metres, which allow to get very precise and perfectly repeteable workings. The afore said working techniques characterized by technologically advanced machineries and the presence of high skilled workers, enable to obtain sandwich panels with high quality performances. The productive structure, working in discontinuous, allows the company to execute the orders without the need of minimun stock and to produce panel with very different features and applications.